Create your bespoke floor

Treatments & Finishings

The beauty and quality of each wooden floor is determined by the care and craftmenship of the hands that created it. This is why the entire Heywood Team holds great pride in the wood flooring products that are produced with passion and total dedication. To make it easier to decide on the wooden floor to order, please be guided by our treatments and finishing options. The surface treatment in combination with the finishing colour, will ultimately determine the look and feel of your chosen floor.

For more specific and personal wishes, our bespoke service allows you to create your own custom floor that best fits your desired style and interior ambiance .

Bevel

As a standard, all our random length wood flooring is supplied with a regular (± 2mm) bevel on the long sides. On request this can also be a micro bevel (± 1mm), handscraped bevel, or antique bevel. Herringbone and Chevron are standard with micro bevel on all 4 sides. Also this can be changed on request. Square edged flooring is only an options in case of ordering unfinished flooring, to be sanded and finished after installation.

Sanding

A wooden floor which has only been sanded and (colour) oiled will have a somewhat more uniform colour tone after oiling than a floor with a textured surface. The grain in the wood will be less accentuated compared to for example a brushed floor. A sanded and colour oiled floor will also show some variation, as the colour oil is absorbed differently in the cross-grain areas of the flooring, that resulted from the sanding.

Brushing

Brushing gives a deeper structure in the grain of the wood, and therefore accentuates the natural grain. In fact it’s the softer parts of the wood that are actually brushed out. By brushing the floor will get a more prominent appearance. In case of colour finishing a brushed floor, the colour will concentrate in- and accentuate the natural structure of the woodgrain. Depending on the colour choosen this effect is also called ‘white washed’ (limed), ‘black washed’, or more generally ‘colour washed’.

Planed-look

Extra fine sanded wood flooring, followed by a soft polishing brush. Colour oiling in combination with this technique will gently accentuate the very softly polish-brushed woodgrain and will provide for a deep and rich appearence. The planed-look surface provides for a calm, smooth and somewhat modern appearance. An elegant ‘premium’ floor.

Chisel Planed

This technique of planing the surface with chisels will accentuate the natural occuring woodgrain and knot features. It will give the surface of the wood, specially around the knots and cracks, a very natural, rough and robust look which makes your floor stand out as a truly natural product. Once oiled it gives the wooden floor a deeper and richer appearance.

Tumble distressed

By distressing a wooden floor it gets the appearence of a naturally aged floor with wear marks which creates the charm of a used floor with its own unique history. When applying a colour finish to the floor, the wear marks will be accentuated even more, enhancing the natural worn look.

Bandsawn

Bandsaw marks in the surface of a wood floor gives the floor a very unique look. The appearance of sawn raw lumber, providing for a warm yet vivid atmposphere. Boards with saw marks are also often used as decorative wall paneling in modern-, contemporary- and vintage style interiors.

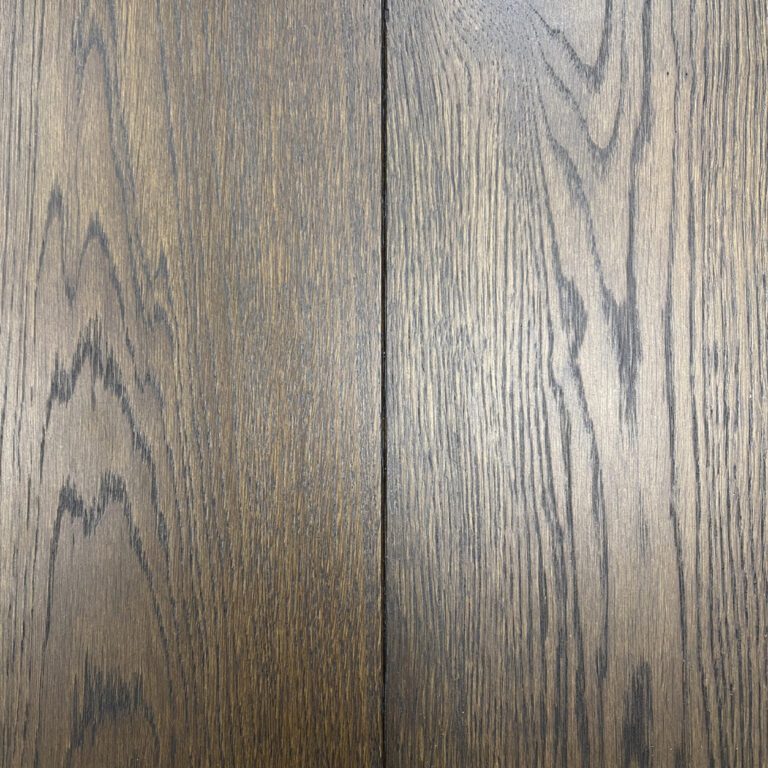

Smoking

By smoking a European Oak wood floor, overall colour tone becomes darker. This effect is stronger with a double smoked treatment, which will give the overall look of the floor an even deeper dark colour. Obviously there will be a beautiful natural colour variation between the individual boards, since not every board will react in the same way to the smoking treatment. For this reason a non-smoked floor, will generally be more uniform in colour then a smoked floor.

After the smoking process, initially the colour or the darkness will be more intense. Sometimes it may have a more antracite or dark greyish appearance than the warmer brown tone that one may expect. However, no worries because this comes with time. Smoked floors become several shades lighter over time, and the colour will eventually turn into a more brown and warmer tone. The darker the initial result, the more shades lighter it will become over time.

Staining

Staining is the process of pre-colouring a wood floor. It is non-protective, yet meant to adjust the base colour of the wood into the direction of the desired final colour of the floor. Often used for creating the appearance of a smoked floor, yet with less colour variation than a real smoked floor, but also for achieving modern light colour effects or the appearance of old weathered wood flooring. Among the different types of available stains there are colour stains and reactive stains. Where the colour stains remain a more stable colour, the reactive stains will react to the wood and lead to more variations over time. After staining and before use, the wood floor requires a protective finishing, like an oil or lacquer.

Finishing

The vast majority of wood flooring produced by Heywood will be treated with a protective natural or coloured finishing. This may be an oxidative (air-dried) oil finishing such as a single coat of 2 component hardwax oil, or a two-coat system. Moreover we also offer prefinishing options like UV curing or lacquering.

Bespoke flooring

Design your own custom floor together with Heywood.

Next to the extensive collection range presented at our website, there exist also possibilities for developing your personal flooring wishes together with Heywood. From modern and contemporary to traditional and classic styles. Whichever your interior design intentions are, together with us a suitable bespoke floor can be created.